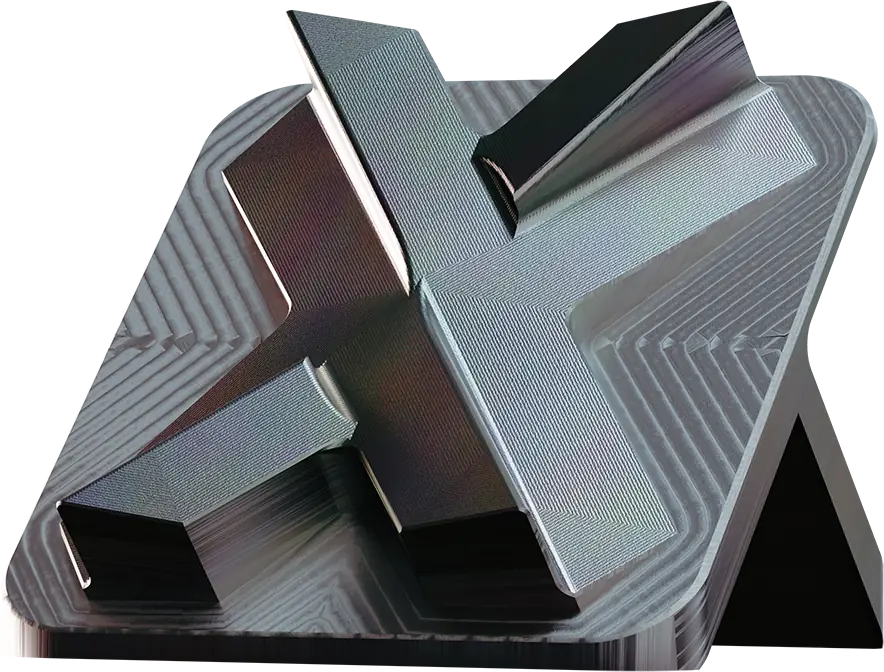

The Most Efficient Way to Source CNC Machined Parts

Source all your CNC machining jobs, from prototyping to high-volume production, reliably in one place. Xometry offers massive capabilities with 10,000 manufacturers across China and globally. Advanced AI technology, combined with attentive customer care, ensures a seamless experience from instant quotes to order tracking.

The Easiest Way To Manage Your Projects

1. Upload Your CAD Files

Effortlessly upload one or multiple designs to receive quotes for up to 20 parts simultaneously.

2. Customise Your Quote

Easily adjust quantities, select materials, finishes, colours, and required certifications, all through our intuitive interface.

3. Confirm & Track Your Order

Sit back as we audit your design, manage production, ensure quality control, and deliver your parts on time.

The Advantages of Our Digital Manufacturing Platform

Massive Network Capacity

Access the production capacity of over 10,000 qualified manufacturers worldwide, offering a wide range of production capabilities and certifications. Our extensive network enables the production of parts with any level of complexity, in almost any material, with precise tolerances and the required post-processing.

Human Expertise Behind Every Order

Our experienced team ensures smooth order management at every step. From initial design checks to seamless communication with manufacturing partners, we provide personalised feedback and suggest design improvements to optimise your parts and production processes.

Flexible Purchasing Solutions

Xometry offers flexible post-payment options for reliable corporate customers, a variety of payment methods to suit your needs, and the ability to establish framework agreements for specific prices and quantities, ensuring cost predictability and streamlined procurement processes.

Quality Assurance

Xometry is ISO 9001:2015 certified. Our seamless Manufacturing Supplier Network integration, in-house applications engineering team, and Xometry Quality Assurance Lab ensure we back every part we ship with top-notch quality.

Fast Delivery across Asia

Xometry delivers parts to most of Asia countries. See your delivery options for instant quotes right away or plan your custom shipments for complex projects.

Certifications & Inspection Reports

Xometry can provide various certificates (compliance with order types 2.1 and 2.2, raw material certificates for metals and plastics, heat treatment protocols, RoHS certificates, etc.) and inspection reports (CMM, First Article Inspection Report – FAIR, measurement reports, etc.).

CNC Machining Materials Quoted Instantly

We price almost any material manually upon your request within 24-48 hours.

Aluminium

- EN AW-2007 / 3.1645 / AlCuMgPb

- EN AW-6060 / 3.3206 / Al-MgSi

- EN AW-6061 / 3.3211 / Al-Mg1SiCu

- EN AW-6082 / 3.2315 / Al-Si1Mg

- EN AW-5083 / 3.3547 / Al-Mg4,5Mn

- EN AW-7075 / 3.4365 / Al-Zn6MgCu

Steel

- 1.0038 / St37-K / S235JR

- 1.0503 / C45

- 1.0570 / St52-3 / S355J2G3

Stainless steel

- 1.4301 / X5CrNi18.10(V2A)

- 1.4404 / X2CrNiMo17-12-2 (V4A)

- 1.4571 / X6CrNiMoTi17-12-2

- 1.7131 / 16MnCr5

- 1.7225 / 42CrMo4

Other metals

- 2.0060 / E-Cu57 / Cu-ETP / CW004A

- 2.0065 / E-Cu58 / CW004A

Ms58 / 2.0401 / - CuZn39Pb3

- Titan Grade 2 / EN 3.7035

- Titan Grade 5 / 6AL-4V9

Plastics

- ABS

- Acrylic

- Acetal / Delrin / POM

- Nylon / Polycaprolactam

- PC / Polycarbonate

- PEEK / Polyether ether ketone

- PEEK Glass-Filled

- PP Polypropylene

- PTFE / Teflon

- PVDF

- UHMW PE / Ultra-high-molecular-weight polyethylene