Industrial 3D Printing Service Online

Source all your 3D printing jobs, from prototyping to high-volume production projects, reliably in one place. Advanced AI technology, combined with attentive customer care, ensures a seamless experience from instant quotes to order tracking.

Express Manufacturing Within 3 Days

Five 3D Printing Technologies

More than 70 Materials

Our 3D Printing Capabilities

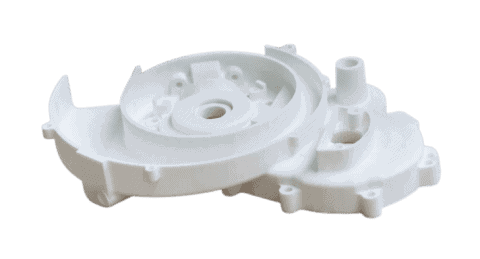

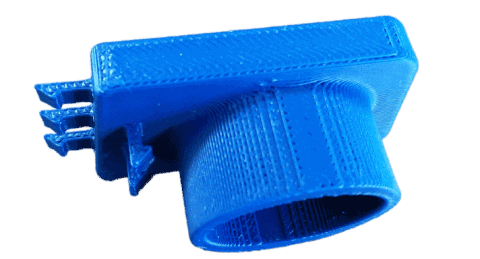

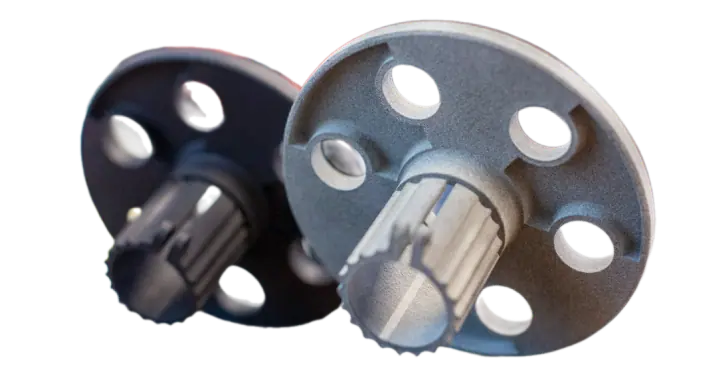

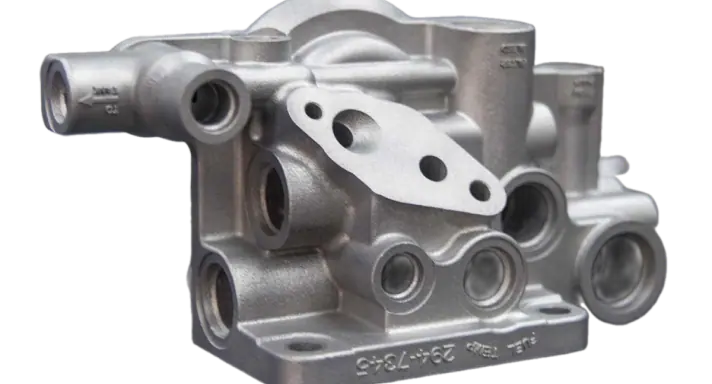

Xometry offers massive capabilities with 10,000 manufacturers across Asia and worldwide. With the

flexibility of 3D printing and the ability to support complex, intricate designs, we provide everything from

functional and visual prototypes in plastic and metal to high-quality end-use parts.

The Advantages of Our Digital Manufacturing Platform

Massive Network Capacity

Access the production capacity of over 10,000 qualified manufacturers worldwide, offering a wide range of production capabilities and certifications. Our extensive network enables the production of parts with any level of complexity, in almost any material, with precise tolerances and the required post-processing.

Human Expertise Behind Every Order

Our experienced team ensures smooth order management at every step. From initial design checks to seamless communication with manufacturing partners, we provide personalised feedback and suggest design improvements to optimise your parts and production processes.

Flexible Purchasing Solutions

Xometry offers flexible post-payment options for reliable corporate customers, a variety of payment methods to suit your needs, and the ability to establish framework agreements for specific prices and quantities, ensuring cost predictability and streamlined procurement processes.

Quality Assurance

Xometry is ISO 9001:2015 certified. Our seamless Manufacturing Supplier Network integration, in-house applications engineering team, and Xometry Quality Assurance Lab ensure we back every part we ship with top-notch quality.

Fast Delivery across Asia

Xometry delivers parts to most of Asia countries. See your delivery options for instant quotes right away or plan your custom shipments for complex projects.

Certifications & Inspection Reports

Xometry can provide various certificates (compliance with order types 2.1 and 2.2, raw material certificates for metals and plastics, heat treatment protocols, RoHS certificates, etc.) and inspection reports (CMM, First Article Inspection Report – FAIR, measurement reports, etc.).

3D Printing Materials Quoted Instantly

Plastics

- 8360X-SLA

- 9400E-SLA

- Ledo6060-SLA

- 高韧性类ABS-进口

- Somos-SLA

- 8100-SLA

- Therm1-SLA

- TAURUS-SLA

- 8220-SLA

- 黑色树脂-SLA

- 尼龙PA12-SLS

- 尼龙PA12 GF-SLS

- 尼龙PA11-SLS

- PA6 GB-SLS

- 尼龙PA12-MJF

- 尼龙PA12 GB-MJF

- 尼龙PA11-MJF

- ABS-FDM

- ASA-FDM

- PA12CF-FDM

- PEEK-FDM

- PLA-FDM

- ULTEM1010-FDM

- ULTEM9085-FDM

- PC-FDM

- PETG-FDM

- PPSU-FDM

- PPS-FDM

- PC-ABS-FDM

- PC-PBT-FDM

- PC-FR-FDM

- PA6/66-FDM

- PA6-CF-FDM

- HPPA-CF-FDM

- HPPA-GF-FDM

- ABS-GF-FDM

- PET-GF-FDM

- PET-CF-FDM

- Victrex AM™ 200FIL-FDM

- WANHUA PA12-FDM

- BASF ULTRAFUSE®

- PPSU-FDM

- BASF ULTRAFUSE®

- PC/ABS-FR-FDM

- Kimya ABS-ESD-FDM

Elastomers

- TPU 88A-SLS

- HP TPU-SLS

Metals

- Aluminum-Aisi10mg-SLM

- Stainless steel-316L-SLM

- Titanium-TC4-SLM

Comparison of our 3D printing capabilities

Use the dropdowns in each column to select and compare services side by side.

Use the dropdowns in each column to select and compare services side by side.

|

Affordable & large format prototypes and end-use parts Get a Quote

|

Strong and functional prototypes & low-volume production Get a Quote

|

Metal parts with complex designs Get a Quote

|

Strong and functional prototypes & low-volume production Get a Quote

|

Visual prototypes with high resolution Get a Quote

|

|---|---|---|---|---|

Technology DescriptionFused Deposition Modeling (FDM) 3D printing is cost-effective and widely known for its great material selection, accuracy, and the possibility to print large, functional plastic parts. | Technology DescriptionMulti Jet Fusion (MJF) 3D printing is one of the most widely used industrial additive manufacturing processes. Like SLS, MJF is used to produce strong, functional plastic parts. | Technology DescriptionSelective Laser Melting (SLM) 3D printing melts together small particles of metal powder to create complex parts using a wide range of metals, from aluminium to stainless steel or nickel alloys like Inconel. | Technology DescriptionSelective Laser Sintering (SLS) 3D printing is one of the most widely used industrial additive manufacturing processes. Like MJF, SLS is used to produce strong, functional plastic parts. | Technology DescriptionStereolithography (SLA) 3D printing utilizes light-curable thermoset resins to build highly accurate, high-resolution parts. Its surface finish is one of the highest standards in the industry and recommended for aesthetic prototypes. |

Lead Time4 days | Lead Time4 days | Lead Time6 days | Lead Time5 days | Lead Time3 days |

Maximum Part Size780x750x1000 mm | Maximum Part Size380x380x284 mm | Maximum Part Size420x420x450 mm | Maximum Part Size350x520x350 mm | Maximum Part Size1400x700x550 mm |

Instant quote availabilityYes | Instant quote availabilityYes | Instant quote availabilityYes | Instant quote availabilityYes | Instant quote availabilityYes |

General Tolerance0.5% | General Tolerance0.3% | General Tolerance0.2% | General Tolerance0.30% | General Tolerance0.3% |

Standard Layer Thickness0.25 mm | Standard Layer Thickness0.08 mm | Standard Layer Thickness0.05 – 0.1 mm | Standard Layer Thickness0.1 mm | Standard Layer Thickness0.02 mm |

Minimum Feature Thickness0.50 mm | Minimum Feature Thickness0.30 mm | Minimum Feature Thickness0.75 mm | Minimum Feature Thickness0.60 mm | Minimum Feature Thickness0.50 mm |

Minimum Wall Thickness

| Minimum Wall Thickness

| Minimum Wall Thickness

| Minimum Wall Thickness

| Minimum Wall Thickness

|

Requires Support StructuresYes | Requires Support StructuresNo | Requires Support StructuresYes | Requires Support StructuresNo | Requires Support StructuresYes |

Advantages

| Advantages

| Advantages

| Advantages

| Advantages

|

Disadvantages

| Disadvantages

| Disadvantages

| Disadvantages

| Disadvantages

|

| Explore FDM Further | Explore MJF Further | Explore SLM Further | Explore SLS Further | Explore SLA Further |